The IKEA Method Fixing Energy Megaproject Chaos

Why 9 out of 10 them fail. And the one tool that fixes it.

You are standing on a construction site for a petrochemical plant. It is raining.

There are two hundred pipefitters waiting for a specific valve to arrive. The valve is sitting in a warehouse in Houston. The engineering drawings for the pipe rack were updated yesterday, but the foreman is holding the old revision.

This is what burning cash looks like.

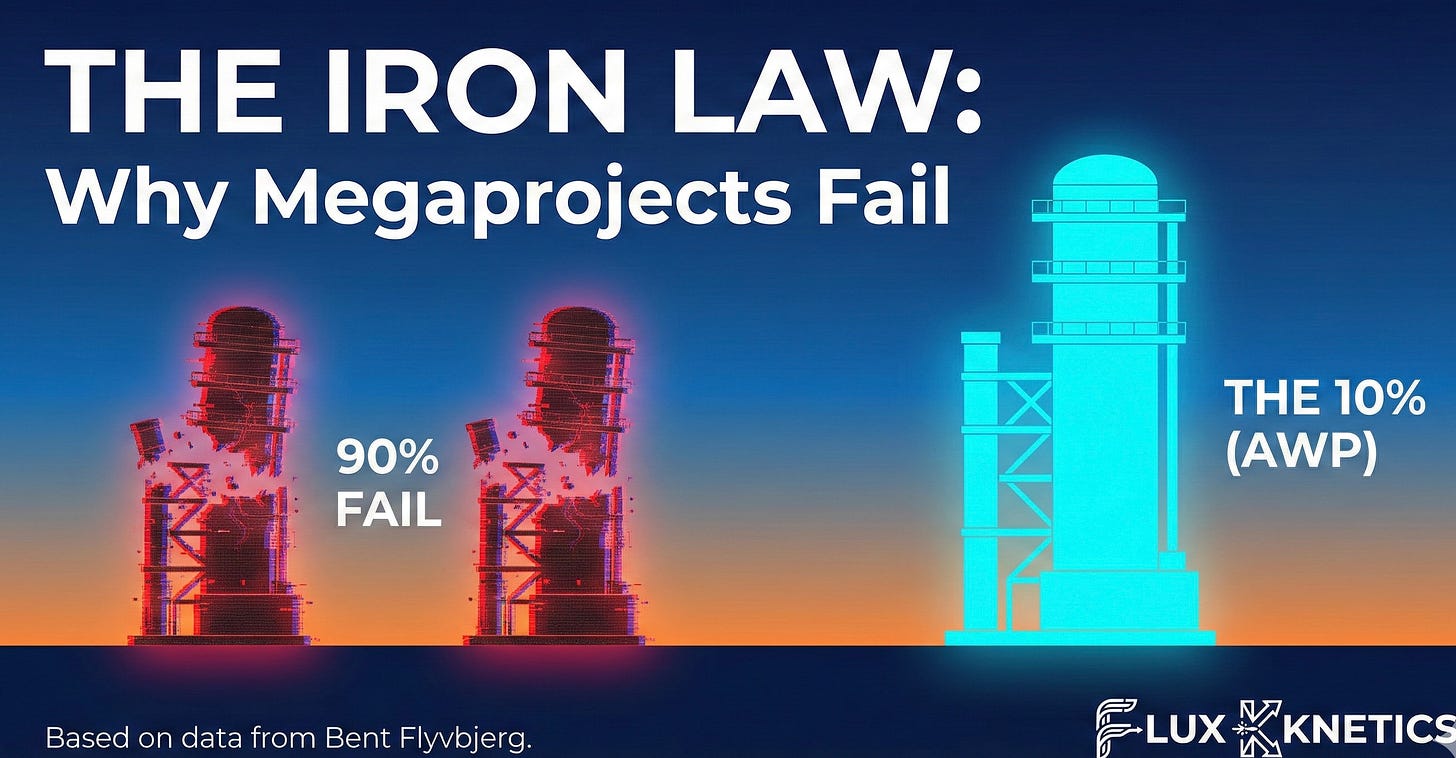

Oxford professor Bent Flyvbjerg calls it the “Iron Law of Megaprojects.” His data suggests that nine out of ten projects exceeding $1 billion go over budget or over time. In the oil and gas sector, the numbers are even grimmer. Independent Project Analysis found that 65%-75% of oil and gas megaprojects fail to meet their objectives.

I have walked these sites for more than a decade. The problem is rarely that we do not know how to build. The problem is the sequence.

We try to build these massive assets the way a chef cooks a meal. A little bit of this, a little bit of that, adjusting on the fly. But you cannot improvise a billion-dollar asset.

There is one technique that fixes this. It is the standard for Shell, ExxonMobil, and Dow. It is called Advanced Work Packaging (AWP).

Here is how it works. And here is how you can use it to stop the bleeding.

The IKEA Principle

Think about the last time you bought a piece of IKEA furniture.

Imagine if you opened the box and found a pile of wood, a bag of 400 mixed screws, and a drawing of the finished desk. No step-by-step guide. Just the goal and the parts.

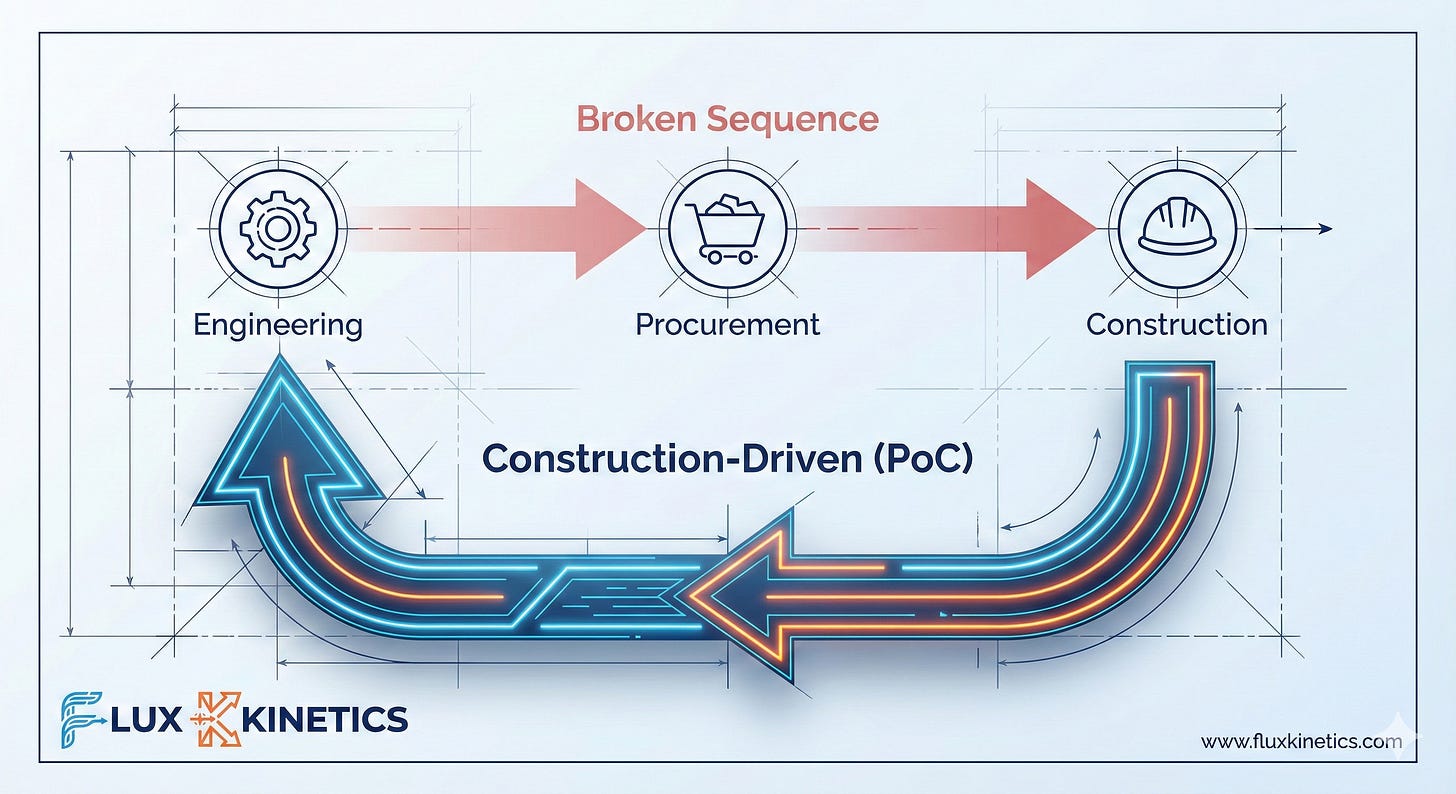

That is how we traditionally run energy projects. Engineering throws drawings over the fence to Procurement. Procurement buys materials in bulk to get a discount. Construction receives a pile of steel and a stack of drawings and has to figure out how to assemble it.

Now imagine the IKEA box again.

You open it. You find “Pack 1.” It contains exactly two boards and four screws. You open the instructions. Step 1 shows you how to connect those two boards using those four screws. You cannot mess it up.

Advanced Work Packaging is the IKEA-ification of industrial construction.

It flips the entire project lifecycle. Instead of “Engineering-Driven” (where engineers design by system, like ‘Fire Water’), it is “Construction-Driven.”

This different approach allows the construction team defines the Path of Construction (PoC) before a single drawing is made. They tell engineering, “We are building the North Corner first. We need drawings for the North Corner by January. We do not care about the South Corner yet.”

The 15% Difference

Does this actually work?

Look at “Company D,” a major oil sands operator in Alberta. They had a critical project. They needed to relocate massive mine trains during a 65-day shutdown. If they missed the window, production would drop 50%, costing millions a day.

They did not just plan. They used AWP to break the scope down into tiny, executable chunks called Installation Work Packages (IWPs). Each package was a single crew’s work for a single week.

The result?

They finished the project 15% under the total budget. They hit every schedule milestone. In an industry where 50% cost overruns are normal, coming in 15% under is a statistical miracle.

Or look at Shell’s Pennsylvania Chemicals project which demonstrates AWP’s coordination benefits. Bechtel and Shell used AWP to manage over 9,000 workers at peak construction on a complex brownfield site. While the project faced global supply chain disruptions, AWP enabled coordination of millions of work hours without the site grinding to a halt, ensuring crews had the right materials when they reached the workface.

Your Strategy: The 3-Step Pivot

You do not need to be building a billion-dollar cracker to use this. You can apply this logic to a solar farm installation or a refinery turnaround tomorrow.

Here is your strategy to implement the “Path of Construction” mindset.

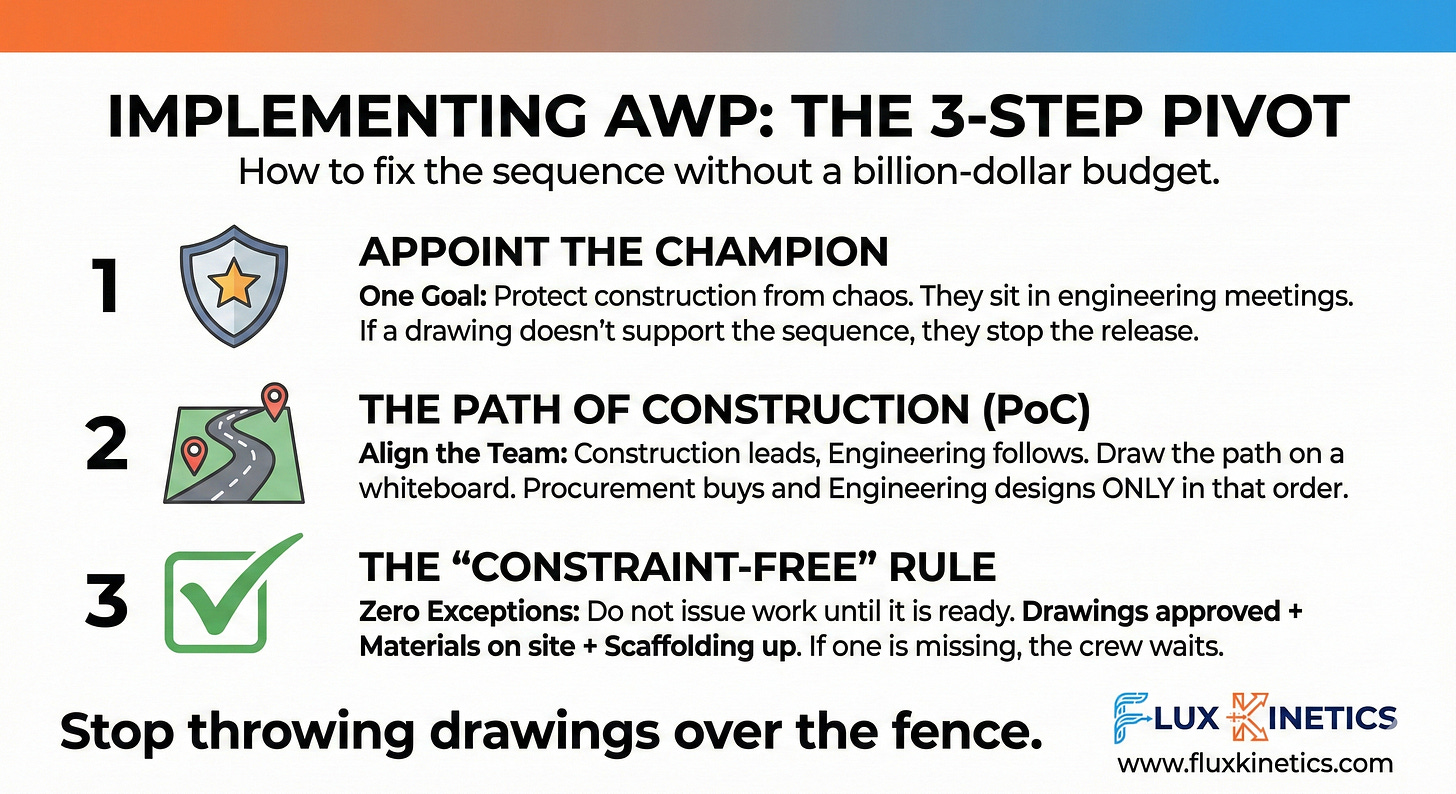

Step 1: Appoint the Champion You cannot do this by committee. You need one person. The AWP Champion. Their only job is to protect the construction team from chaos. They sit in engineering meetings and ask one question. “Does this drawing release support the construction sequence?” If the answer is no, they stop the release.

Step 2: The “Path of Construction” Workshop Before you sign a single contract, get your construction manager, your lead engineer, and your procurement officer in a room. Draw the site on a whiteboard. Ask the construction manager, “Where do you want to start?” Once they draw the path, force the others to align. Procurement must agree to buy materials in that order. Engineering must agree to design in that order.

Step 3: The “Constraint-Free” Rule This is the hardest rule to follow. Make a rule for your field supervisors. Do not issue work to a crew unless it is constraint-free. That means every drawing is approved, every bolt is in the bag, and the scaffold is up. If one thing is missing, keep the package in the office. It is better to have a crew wait for an hour than to have them start, stop, look for materials, and wait for six hours.

The Bottom Line

The modern energy will require trillions of dollars in new infrastructure. We cannot afford to waste 20% of that capital on inefficiency.

Stop throwing drawings over the fence: Build the instructions first.

Thanks for reading Flux Kinetics.

If you found this breakdown valuable, help us grow the community. Share this article with a project manager who is currently drowning in spreadsheets.

Also, I want to hear from you. Have you seen AWP work in the wild? Or have you seen it fail? Reply to this email or leave a comment below. I read every single one.

Flux Kinetics - Where energy meets intelligence,

Wassim C.

This content is for educational purposes only and does not constitute financial, legal, or tax advice. All opinions and analyses are my own, and any actions you take are at your own risk after consulting an appropriate professional.