Tesla: 168 Days. You: Endless To-Do Lists.

5 billion-dollar Energy Execution Systems you can steal today.

Tesla built Shanghai Gigafactory from dirt to production vehicles in 168 working days. That timeline should have consumed three years. Offshore wind installations coordinate 10,000 discrete components across continents, deliver power to millions, hit financial targets within 2% variance. Meanwhile, you can’t sustain a fitness routine past February.

The gap isn’t motivation. It’s not discipline. It’s architectural malpractice.

You’re operating a multi-million-dollar entity (your life, your career, your potential ROI) with management infrastructure suited for a weekend yard sale. Energy megaprojects move billions of dollars and reshape economies because they’ve engineered execution systems that remove human weakness from the critical path. These aren’t cute metaphors about “applying business thinking” to personal goals. This is structural engineering for outcomes, and every principle scales perfectly to individual deployment.

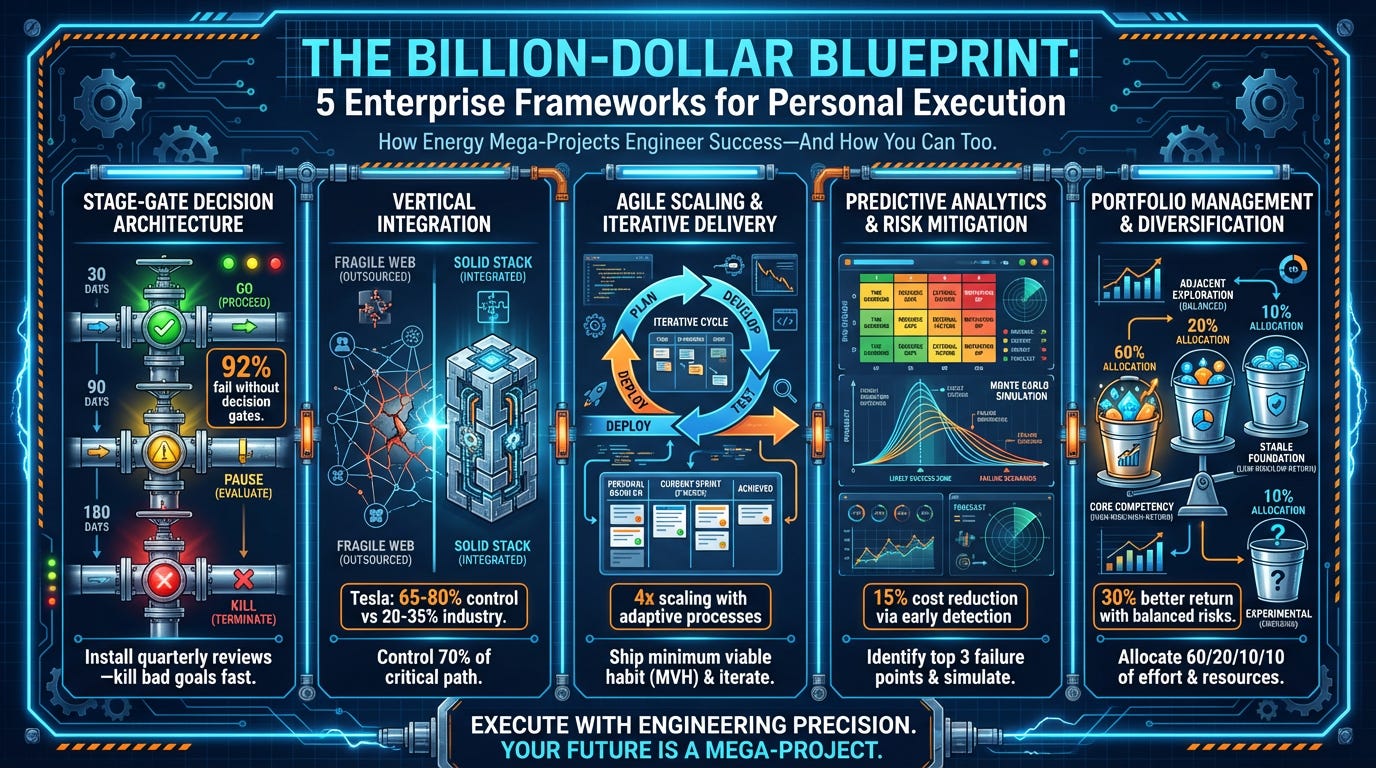

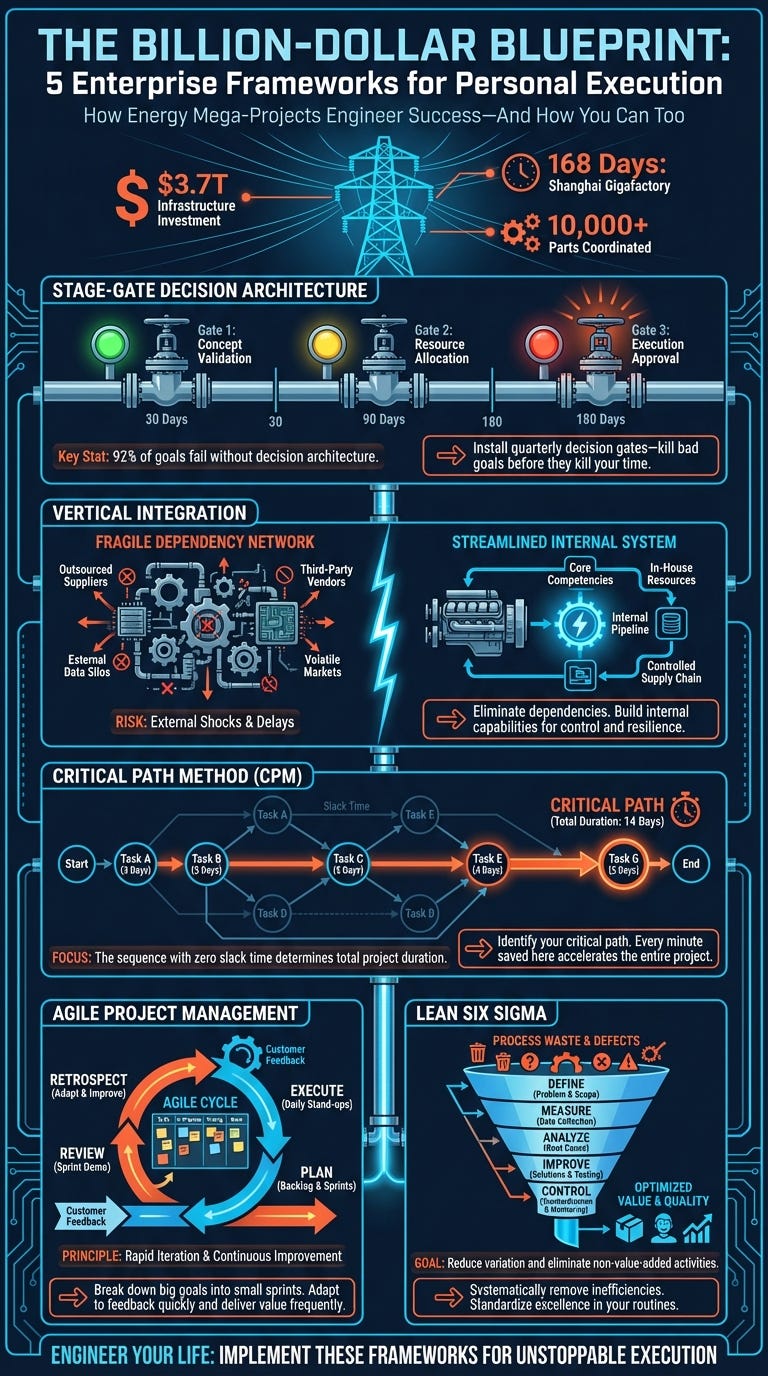

After dissecting projects from Tesla’s manufacturing revolution to Malaysia’s $3.7 trillion infrastructure frameworks, five specific operating systems emerge. They’re not motivational. They’re mechanical. And they work because they bypass the psychological failures that doom 92% of personal goals before March.

1. Stage-Gate Architecture: The Surgical Art of Killing Your Own Projects

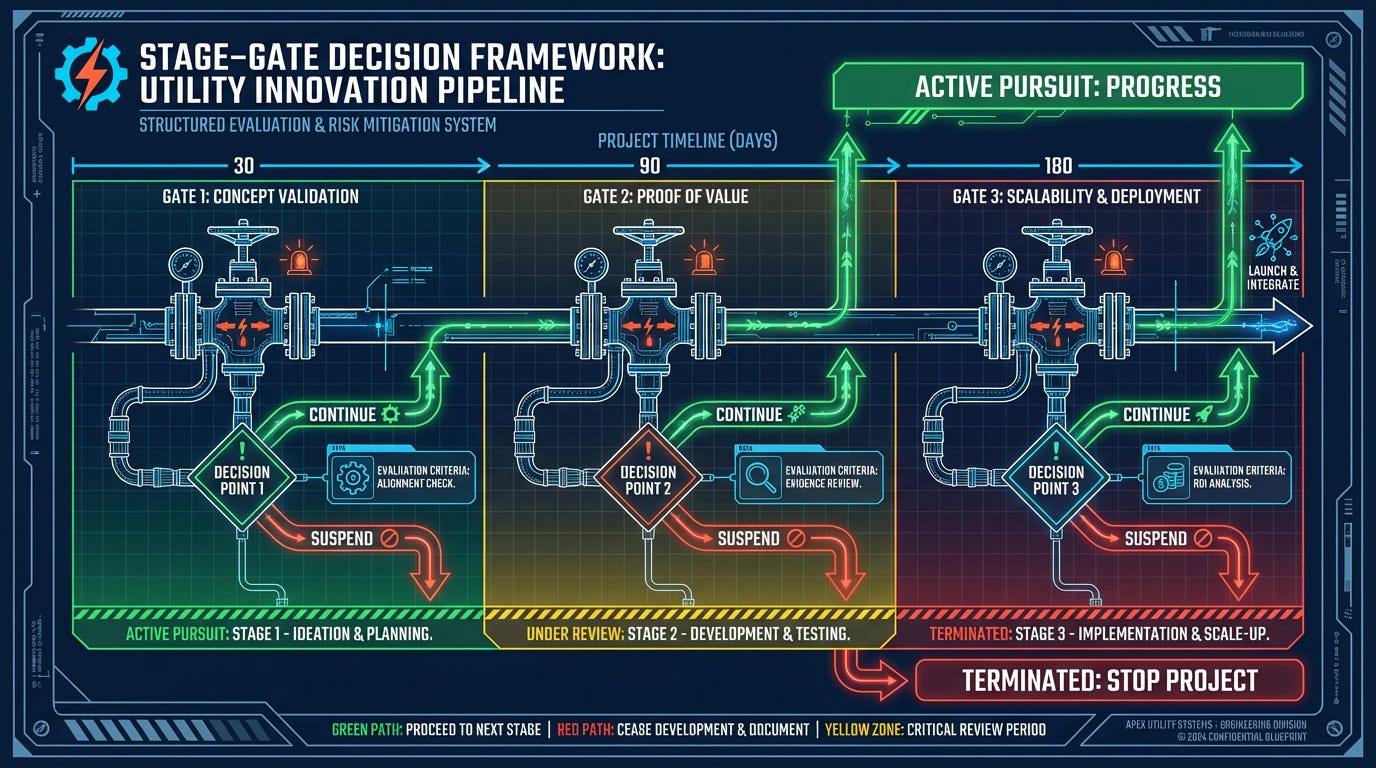

France’s infrastructure authority Fin Infra operates with mandatory stage gates at every critical milestone. Projects don’t gradually fade into irrelevance or limp forward on inertia. They face explicit continuation decisions based on updated data, current conditions, and evolving priorities. The system forces a binary choice: double down with conviction or terminate with prejudice.

When Malaysia’s National Planning Committee builds five-year infrastructure plans, they install feedback loops that mandate periodic reality checks. Not optional reviews. Not “let’s see how it goes” optimism. Structured reassessment of necessity and viability against hard evidence. This is why projects managing billions don’t collapse from scope creep. They have architectural off-ramps built into the foundation, exits designed before groundbreaking.

Your goals lack this entirely.

You set targets in January fueled by New Year conviction, then watch them slowly asphyxiate under the weight of changing circumstances, competing priorities, and new information. But you keep going because quitting feels like failure. This is loss aversion, the cognitive bias that treats sunk costs as justification for continued investment. Infrastructure eliminates this through benefit-cost analysis on net present value terms. They evaluate future potential against current expenditure, completely divorced from historical commitment.

Install three decision gates into your execution calendar. First gate at 30 days: does this goal still align with current priorities, or are you persisting out of guilt and social commitment? Second gate at 90 days: what tangible evidence suggests this trajectory leads to the stated outcome? If you were advising someone else showing your exact results, would you recommend continuation? Third gate at 180 days: given actual ROI measured in time, energy, and observable progress, does this deserve another resource cycle?

Create a formal review process. Treat it like a board meeting with yourself as both CEO and investor. Plot each active goal on two axes: impact potential (1-10) and current trajectory (declining, flat, ascending). Anything scoring below 5 on impact with flat or declining momentum gets suspended immediately. Not “given more time.” Not “revisited next quarter.” Killed. Resources reallocate to higher-yield opportunities.

The psychological barrier sits right here. Most people experience goal abandonment as personal failure rather than intelligent portfolio management. Infrastructure projects prove the opposite: strategic termination is a core competency, not a character flaw.

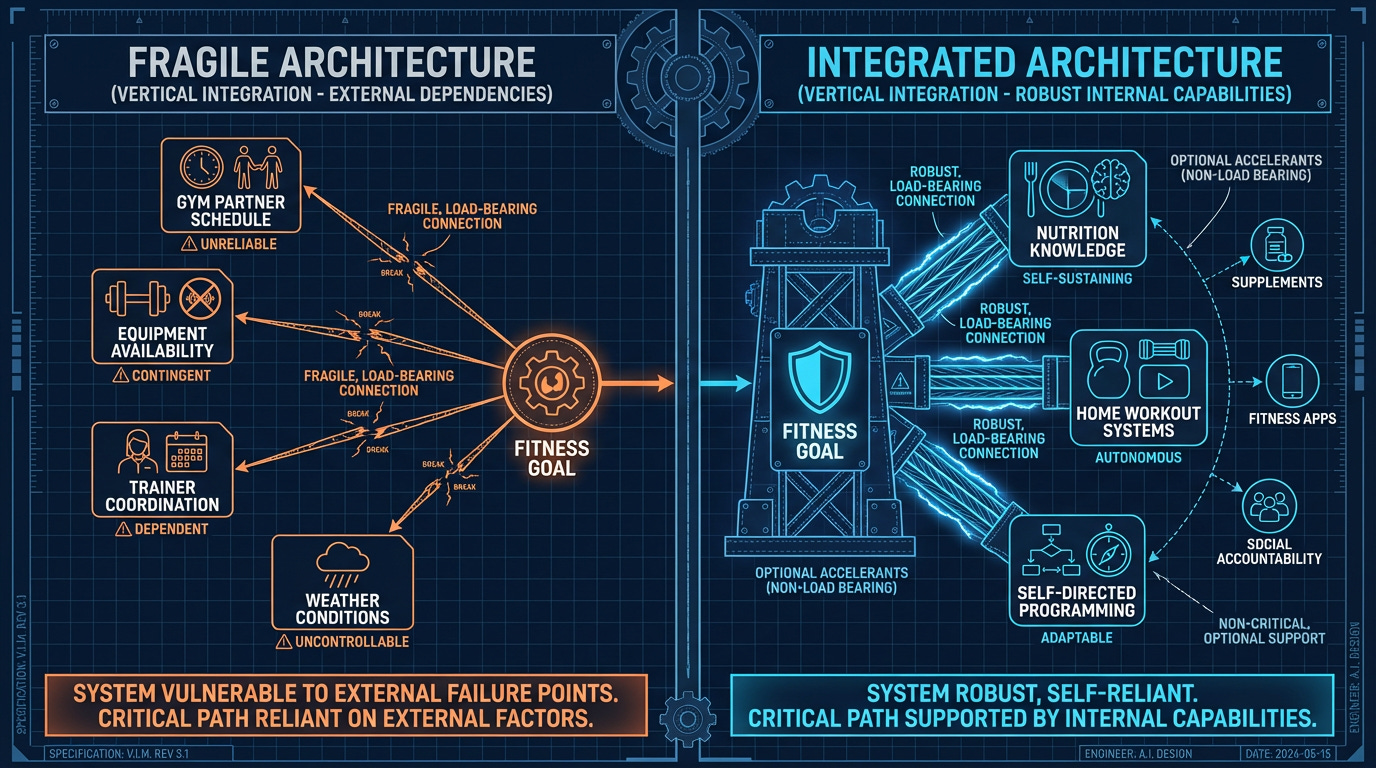

2. Vertical Integration: Stop Building on Ground You Don’t Own

Tesla manufactures batteries, software, motors, seats, and charging infrastructure in-house. Traditional automakers outsource 65-80% of components to supplier networks. When problems surface at Tesla, internal teams pivot within days. When problems hit Ford or GM, they enter supplier negotiations, wait for external fixes, coordinate across organisational boundaries they don’t control. Speed differential compounds over time.

This extends across infrastructure at scale. Best-in-class governments maintain unified planning definitions, standardised parameters, and cross-sectoral integration. Their transportation decisions don’t operate independently from energy planning. Water infrastructure connects to urban development. Everything feeds into a single source of truth. They control the critical architecture.

Audit your goal dependencies right now. Where are you building execution plans on variables outside your control? Where does achievement require coordination with other people’s schedules, external systems, or fragile partnerships?

Weak integration looks like this: “I’ll get fit when my gym buddy commits to a schedule.” “I’ll launch that side project when I have more support from my network.” “I’ll start the business when market conditions improve.” You’ve architected these goals to require permission, cooperation, or favorable external conditions before you can even begin. Structurally, they’re doomed.

Vertical integration redesigns for self-sufficiency: “I control my nutrition protocol, training schedule, and recovery system. A workout partner would accelerate results, but they’re not on the critical path.” “I’m building the MVP with skills I currently possess. External capital would scale faster, but it’s not blocking launch.” “I’m starting with a service model that generates revenue immediately. Market expansion comes later, but it’s not preventing day-one operations.”

Most personal goals fail because of outsourced accountability. You’ve made your success contingent on variables you can’t influence. Energy projects succeed because they identify critical path components and either control them directly or build redundancy that eliminates single points of failure.

Apply the 70% rule. If achieving your goal requires more than 30% coordination with external parties or systems, it’s architecturally fragile. Redesign immediately. Make self-sufficiency the foundation, treating external collaboration as an accelerant rather than a prerequisite.

Map your dependency tree for each major goal. Identify what requires other people to cooperate, external systems to function, or favorable conditions to persist. Then aggressively redesign to control 70% of the critical path yourself. For the remaining 30%, either build redundancy (multiple paths to the same outcome) or pursue vertical integration through skill acquisition. Learn the capability yourself rather than depending on someone else to provide it.

3. Data-Driven Forecasting: Your Intuition Is Systematically Wrong

When governments plan water infrastructure, they calculate total future demand using population forecasts, consumption per capita projections, transmission loss factors, and reserve capacity margins. For power generation, they model capacity requirements from GDP growth analysis, peak demand projections, and system flexibility needs. They don’t guess. They don’t use aspirational thinking. They build mathematical models that connect inputs to required outputs with quantifiable precision.

Tesla operates the same way. Every decision flows from real-time data, not executive intuition. Their Full Self-Driving development uses billions of actual driving miles to train algorithms. Not simulations. Not test track data. Real-world telemetry at massive scale. When Tesla struggled with Model 3 production, they didn’t “try harder.” They measured bottlenecks, quantified throughput at each station, and mathematically determined where capacity expansion generated maximum output improvement.

McKinsey’s research on infrastructure planning reveals that leading governments deploy standardised planning parameters across all agencies. Common assumptions about growth rates, utilisation targets, and capacity thresholds. This eliminates coordination failures where different departments operate from incompatible models of reality.

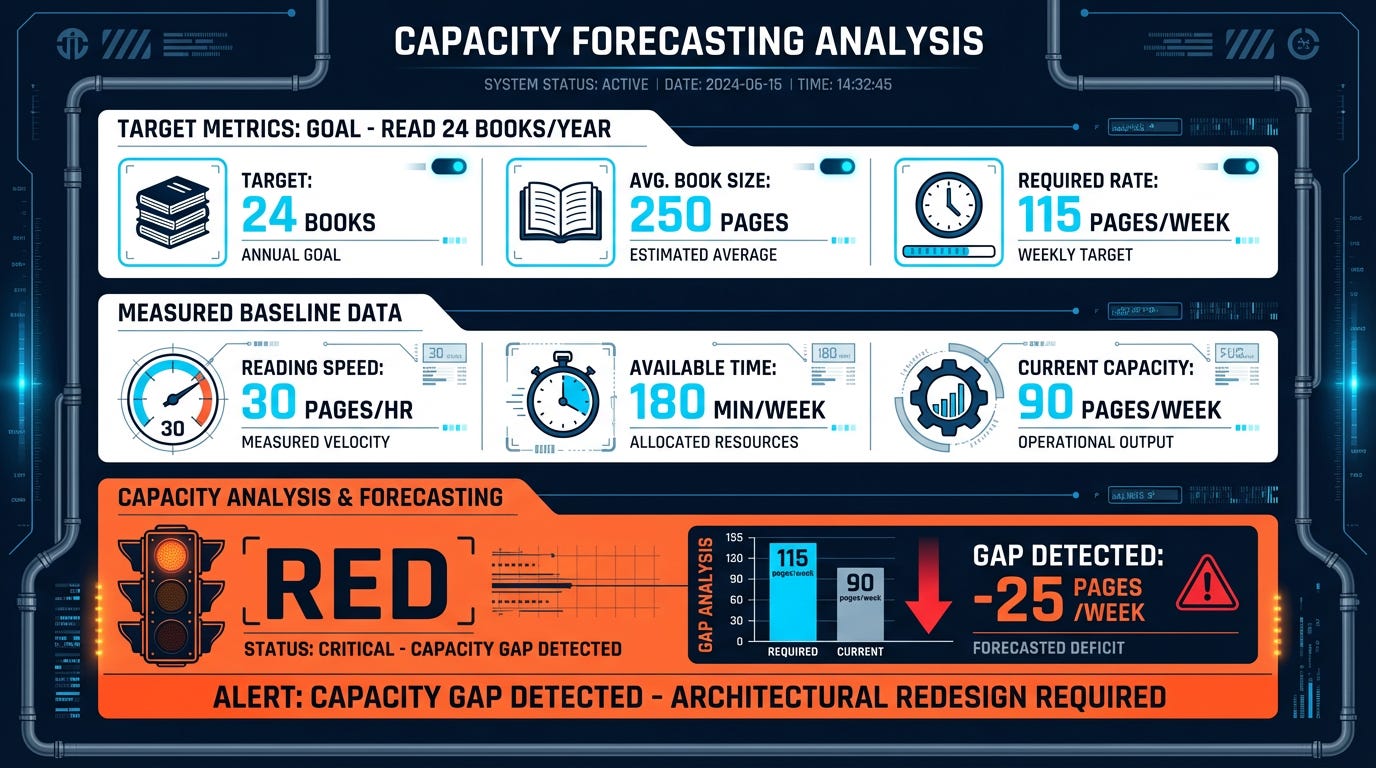

You are lying to yourself about your capacity.

Not maliciously. Just naturally. Human brains are terrible at estimating available time, sustainable effort, and realistic progress rates. The gap between what you think you can accomplish and what you can actually deliver isn’t small. It’s structural. And it’s why most goals collapse within weeks.

Deploy infrastructure-grade forecasting instead of motivational goal-setting. Pick a concrete target and work backward with measured data.

Example: “I want to read more books” is useless. Transform it into an engineering problem. Target outcome: 24 books annually. Average book length: 250 pages. Required weekly throughput: 24 books × 250 pages ÷ 52 weeks = 115 pages weekly. Now measure your actual baseline. Track five reading sessions. Calculate your genuine pages-per-hour rate. Maybe it’s 30 pages. Now audit available time. Don’t estimate. Track for two weeks. Count discretionary minutes actually available for reading after subtracting work, sleep, meals, essential obligations, and realistic recovery time. Maybe you find 180 minutes weekly.

Run the math: 30 pages per hour × 3 hours weekly = 90 pages maximum capacity. You’re 25 pages short every single week. With current architecture, the goal is mathematically impossible. Not hard. Not requiring more discipline. Impossible.

You have three options. Increase reading speed through training (speed reading courses, practice). Expand available time by eliminating lower-value activities. Or adjust the target to match reality (reduce to 18 books, which your current capacity supports). What you cannot do is ignore the math and hope motivation bridges a structural capacity gap.

The psychological barrier is cognitive dissonance. Data that contradicts your self-image triggers discomfort, so most people avoid measurement entirely. Infrastructure projects eliminate this through single source of truth systems. Malaysia’s Department of Statistics consolidates data across government agencies so everyone operates from identical reality, not competing narratives or wishful projections.

Measure your actual baseline performance and available capacity for two weeks minimum. Use this data to calculate realistic targets based on what you can currently deliver, not what sounds impressive. If the math doesn’t work, change the approach, expand capacity, or adjust the timeline. But don’t change the measurement. Reality doesn’t negotiate.

4. Agile-Lean Hybrid: Velocity Generates Data That Perfection Never Produces

Tesla merged Silicon Valley agile methodology with lean manufacturing principles in ways traditional automakers cannot replicate. Agile enables rapid iteration, short development cycles, and continuous adaptation. Lean eliminates waste, optimizes workflows, and maintains just-in-time resource deployment. The combination allows Tesla to move fast while scaling to mass production volumes.

They created over 300 Model 3 prototypes in months. Each iteration addressed specific technical challenges identified in the previous version. When automation failed during production hell, they didn’t spend months analyzing the perfect solution. They built a functional production line inside a tent in three weeks, then refined it based on operational data. This is fail fast, learn faster in industrial practice.

Tesla’s philosophy: ship the 80% solution, gather real-world feedback, iterate based on evidence. This beats spending years perfecting a design that might be obsolete at launch. They compress automotive development cycles from 5-7 years down to months by treating development as a series of rapid experiments rather than a single massive planning phase followed by execution.

Infrastructure uses similar principles through modular construction. Tesla’s Shanghai Gigafactory deployed simultaneous work on multiple sections, 24/7 construction schedules, and dual-track approval processes. They moved forward with construction while permits processed in parallel rather than waiting for sequential completion. Execution and planning happened concurrently.

You are moving too slowly because you’re treating personal goals like waterfall projects that require complete planning before any action. The energy sector proves that velocity creates data, and data enables precision you cannot achieve through planning alone.

Stop preparing. Stop “getting ready.” Stop perfecting your approach before launching. You don’t need more planning. You need more iterations.

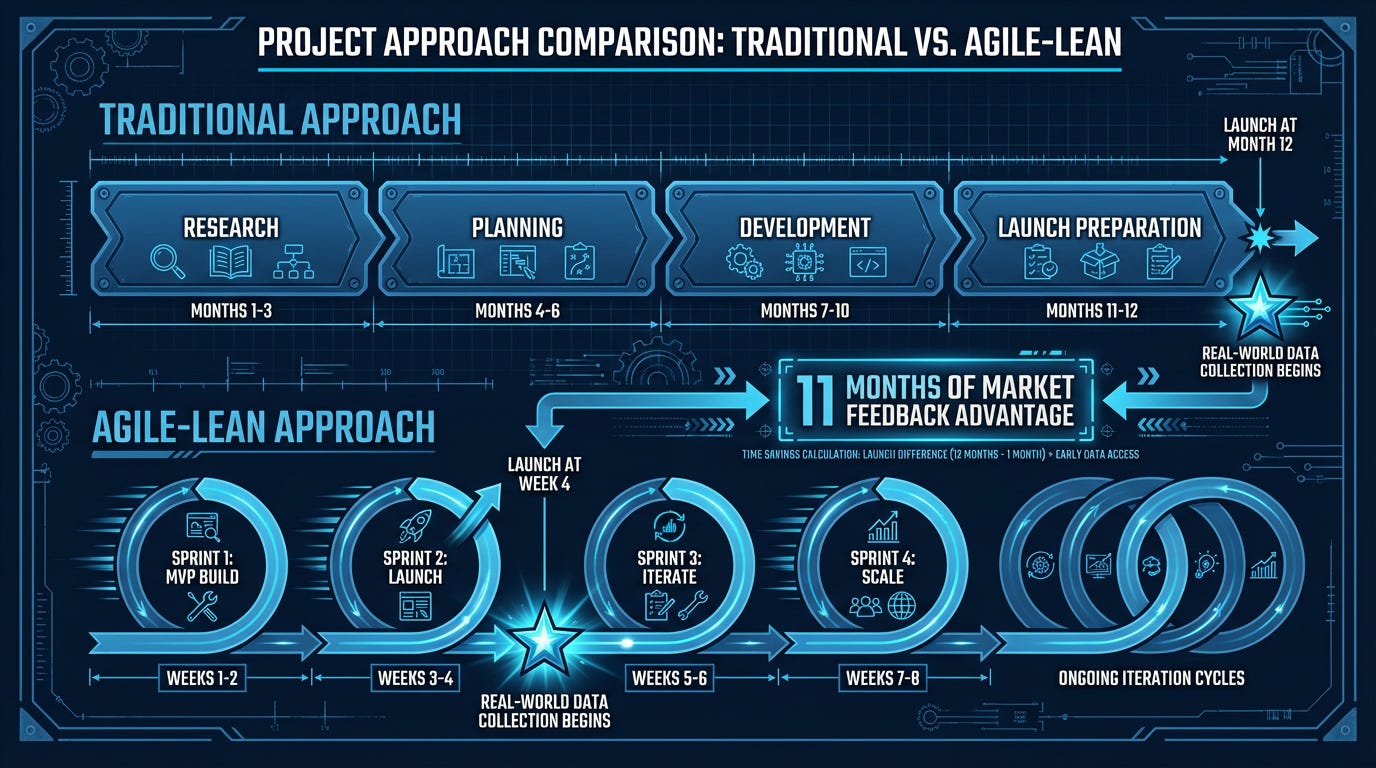

Traditional approach: “I’ll start my side business when I have the perfect product developed, complete brand identity finalized, six months of content planned, website polished, and full marketing strategy mapped.” You’ll still be planning in 18 months.

Agile-lean deployment: Week 1-2, create minimum viable version of your core offering even if it’s embarrassingly basic. Week 3-4, launch to real customers or audience even if you’re mortified by the rough edges. Week 5-6, iterate based on actual feedback from real users, not imagined concerns from your planning sessions. Week 7-8, double down on elements that generated traction, kill what didn’t work, repeat the cycle.

The psychological barrier is fear of imperfection. Launching something flawed feels like it reflects poorly on your competence. Infrastructure projects overcome this through cultures that celebrate rapid iteration over cautious perfection. They’ve institutionalized the understanding that real-world feedback beats theoretical planning, and market data beats internal debate.

Set a hard 7-day deadline. Take whatever you’re “getting ready” to launch and ship a minimally viable version within one week. Don’t make it good. Make it exist. Use actual user response to guide iteration two, not your internal anxiety about what people might think.

This applies to fitness goals, skill acquisition, business launches, creative projects, networking initiatives, everything. The pattern repeats: minimum viable action within 7 days, real-world exposure within 14 days, iteration based on evidence by day 21. Speed generates data. Data enables course correction. Course correction produces outcomes.

5. Cross-Functional Integration: Your Life Departments Are at War

Tesla deliberately destroys departmental silos by organizing around cross-functional teams responsible for complete vehicle systems rather than isolated functions. Instead of separate design, engineering, manufacturing, and quality departments handing work between organizational walls, integrated teams own outcomes end-to-end. This creates direct communication, unified accountability, reduced handoff delays, and holistic problem-solving.

Infrastructure leaders extend this principle through bilateral coordination mechanisms. Canada’s Infrastructure Canada publishes project pipelines publicly and maintains active feedback loops where post-completion analysis feeds directly into next planning cycle. Singapore’s Virtual Singapore digital twin forces all urban planning decisions to consider interconnected infrastructure impacts across transportation, energy, water, and development simultaneously.

Best-in-class organizations deploy sector-agnostic metrics that allow direct comparison across completely different project types. This prevents siloed thinking where transportation, energy, and social infrastructure operate with incompatible priorities or competing resource allocation frameworks.

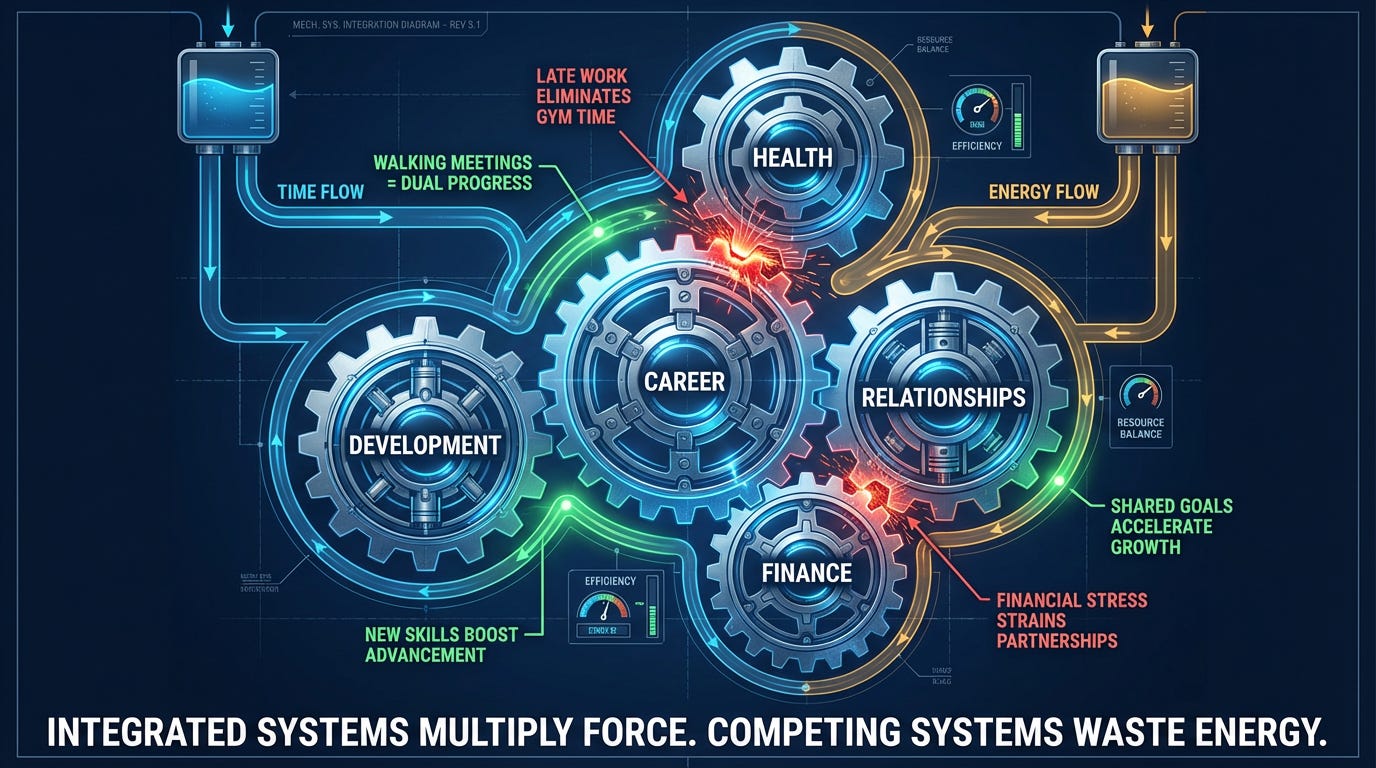

Your life has departments too. Career. Health. Relationships. Finance. Personal development. And they’re probably competing rather than collaborating, waging internal resource wars you’re not consciously managing.

Career goals cannibalize health goals when late work consistently eliminates gym time. Financial goals conflict with relationship goals when side hustle hours consume family availability. Personal development goals starve social connection when learning happens in isolation rather than collaborative environments. Each domain pursues its own objectives without coordination, creating zero-sum competition for the same pool of time, energy, and attention.

Energy projects succeed through integration layers: shared data standards, coordinated planning forums, joint investment mechanisms that force alignment across subsystems. You need identical architecture.

Stop managing goals in isolation. Create a monthly cross-functional integration meeting with yourself. This isn’t optional reflection time. It’s mandatory coordination between your life’s operating divisions.

Agenda items: Resource allocation review (where is time and energy actually flowing compared to stated priorities?). Conflict resolution (which goals compete for identical resources, and what’s the strategic priority ordering?). Synergy identification (how can health goals accelerate career performance? How can relationship goals enhance financial outcomes? Where can single actions serve multiple domains?). Portfolio rebalancing (based on results data, does the current mix need adjustment?).

The psychological barrier is compartmentalization, treating different life areas as separate systems rather than interconnected functions drawing from shared resource pools. Infrastructure proves that integration reduces waste and amplifies outcomes by eliminating internal competition and creating compound effects.

Map your current life departments and their resource demands. Identify conflicts where goals actively compete. Redesign for integration by finding specific ways to make major goals mutually reinforcing instead of competitive.

Example transformation: “Health goal: gym 5x weekly” competes with “Career goal: expand professional network.” Integration redesign: “Walking meetings with industry contacts.” Now relationship-building and fitness operate as a single integrated activity. One hour delivers progress in two domains. The resource conflict disappears, and both goals advance simultaneously.

Find two to three integration opportunities where you can stack goal progress. Make your major objectives support each other rather than fight for the same calendar slots.

Why 92% of Personal Goals Collapse While Gigafactories Don’t

Clinical psychology research documents the carnage. Over 92% of personal goals get abandoned, most within weeks of initiation. Over 40% of adults attempting behavior change give up before establishing any sustainable pattern. This isn’t a motivation crisis. It’s an architecture failure.

The psychological barriers have names: loss aversion (fear of “failing” prevents decisive pivoting), status quo bias (existing patterns feel safer than restructuring even when they’re not working), fear of incompetence (starting imperfectly triggers shame), inadequate planning (goals exist as wishes rather than engineered systems), low trust in process (without data validation, motivation erodes under uncertainty).

Energy infrastructure succeeds at institutional scale because they’ve engineered around these human limitations rather than hoping people overcome them through willpower.

They replace motivation with systems. Australia’s Infrastructure Australia establishes 15-year financial envelopes, removing daily motivation from the execution equation. The budget exists. Projects proceed based on criteria, not feelings.

They kill projects proactively. Indonesia’s National Development Planning Agency classifies project pipelines by funding availability and strategic priority every four years, suspending rather than indefinitely dragging forward unviable initiatives. Strategic termination is a core institutional competency, not a failure mode.

They measure relentlessly. Malaysia’s Department of Statistics creates single sources of truth, eliminating self-deception and competing narratives. Data dictates decisions, not optimistic projections or status preservation.

They iterate publicly. Canada publishes infrastructure project pipelines and post-completion analyses, building accountability through transparency. Outcomes become visible, and visibility drives performance.

They integrate by default. Singapore’s Virtual Singapore digital twin forces all urban planning to consider interconnected impacts. You cannot optimize one system in isolation because the model shows downstream effects across all connected infrastructure.

The gap between your execution and infrastructure execution isn’t resources. It’s operating system quality. They’ve turned execution into engineering rather than relying on motivation, discipline, or willpower. These are mechanical systems that function regardless of how anyone feels on Tuesday morning.

The Build Sequence: From Insight to Operating Infrastructure

You understand the frameworks. Implementation follows this sequence.

Phase 1 (Week 1-2): Diagnostic audit. Conduct brutal inventory of current goals and actual resource requirements (measured, not estimated). Document baseline capacity across time, energy, attention using two weeks of real data. Identify critical dependencies and failure points in current goal architecture. Map internal conflicts where different goals compete for identical resources.

Phase 2 (Week 3-4): Architecture redesign. Install stage gates at 30, 90, and 180-day intervals for all active goals with explicit decision criteria. Redesign dependency structures to achieve 70%+ vertical integration on critical paths. Create forecasting models using measured baseline data rather than aspirational targets. Establish cross-functional integration mechanisms for monthly coordination.

Phase 3 (Week 5 onward): Execution deployment. Launch agile-lean rapid prototyping cycles with 2-week sprints and hard deadlines. Implement weekly data collection and dashboard updates tracking actual progress against forecasted capacity. Run monthly cross-functional integration reviews examining resource conflicts and synergy opportunities. Execute quarterly stage-gate decisions with explicit continue, pivot, or kill outcomes for each active goal.

Phase 4 (Ongoing): System optimisation. Conduct post-completion analysis on achieved goals documenting what actually worked versus what you predicted would work. Feed these insights into next planning cycle to improve forecasting accuracy. Pursue progressive vertical integration by acquiring additional capabilities that reduce external dependencies.

The Question That Determines Everything

When Elon Musk slept on Tesla’s factory floor during production crises, he wasn’t performing theater. He was demonstrating hands-on, engineering-first leadership where problems get solved from first principles rather than delegated into bureaucracy. When Singapore built Virtual Singapore, a comprehensive 3D digital twin of their entire urban infrastructure, they created a platform where proposed changes get tested before implementation, not discovered after costly failure.

These aren’t stories of superhuman discipline. They’re examples of superior system architecture defeating the need for heroic individual effort.

The frameworks in this analysis aren’t motivational concepts. They’re mechanical systems. Stage-gate architecture eliminates wasteful persistence on dying goals. Vertical integration removes fragile dependencies. Data-driven forecasting cuts through self-deception. Agile-lean hybrid enables rapid iteration over cautious perfection. Cross-functional integration prevents internal resource wars.

You don’t need more willpower. You need better infrastructure.

The question isn’t whether these principles work. Billion-dollar projects prove they function at scale across decades and diverse conditions. The question is whether you’ll keep operating your life like an improvised garage startup, or whether you’ll install the operating system that built Tesla Gigafactories in 168 days, launched offshore wind farms powering millions, and reshaped energy infrastructure for entire nations.

Your goals deserve the same engineering rigor as a $10 billion infrastructure project.

Time to manage them that way.

What Happens Next

If this framework clicked, share it with someone drowning in unrealized potential. Someone who sets ambitious goals beautifully but executes poorly. Someone with vision but no architecture. Send them this breakdown. It might be the operating system upgrade that changes their execution trajectory permanently.

If you want frameworks like this delivered weekly, join high-performers subscribed to Flux Kinetics. Every week you’ll receive execution frameworks extracted from billion-dollar Energy industries and translated for immediate individual deployment, case study breakdowns showing how sector leaders engineer outcomes at scale, implementation blueprints ready for immediate use (not theoretical concepts), and exclusive deep research.

This isn’t motivation content. It’s infrastructure engineering for human performance.

Flux Kinetics - Where energy meets intelligence,

Wassim C.

This content is for educational purposes only and does not constitute financial, legal, or tax advice. All opinions and analyses are my own, and any actions you take are at your own risk after consulting an appropriate professional.